[Page created in 2024 for translation of original content]

In winter, switch heaters play a crucial role in maintaining rail functionality despite the cold and snow.

A malfunction of the heaters could cause a switch blockage, disrupt train traffic, and result in extremely costly delays.

Typically, inspections are conducted annually, visually, and close to the tracks to check the heaters' ability to warm the rail.

For example, at the Lyon Part-Dieu and Lyon Perrache stations, this inspection requires mobilizing 4 full-time agents for 5 days.

To increase agility and precision in inspecting these installations spanning over 190,000 square meters, using a drone equipped with a thermal camera is a highly effective solution, allowing the inspection to be completed in 2 hours of flight.

Thermal Analysis: Specific Considerations

Thermography, using infrared cameras, can detect otherwise invisible issues such as overheating in installations or insulation defects.

These inspection techniques have specific factors that need to be considered, as various elements can skew the measurements:

- Emissivity of Materials: Infrared radiation emission varies by material. For example, metal emits less heat than skin at the same temperature, making its temperature appear lower to the thermal camera.

- Reflections Caused by Materials: Glass or certain metal surfaces can reflect infrared rays like mirrors.

- Fog: Infrared rays are highly sensitive to humidity, which can dull the image and create a foggy effect.

Considering these subtleties is even more crucial when the variations we seek are subtle.

For instance, when inspecting a residential building, temperature differences may be just a few degrees.

Conversely, an anomaly in an electrical substation can exhibit a discrepancy of over 200 degrees.

Why use drones for switch heaters ?

To respond quickly and safely on railway premises, capture comprehensive data in just a few hours without impacting the network's capacity, we conduct thermal emission analysis remotely using aerial means.

For our client, Infrapôle Rhodanien, we conducted an inspection mission at Lyon Part-Dieu and Lyon Perrache stations.

The client only had to provide us with a layout of the installations and an agent to accompany us on-site. We carried out the data capture on over 100 switch heaters in just 2 hours of flight.

We were able to provide the first results just a few hours after the capture, directly from our online platform.

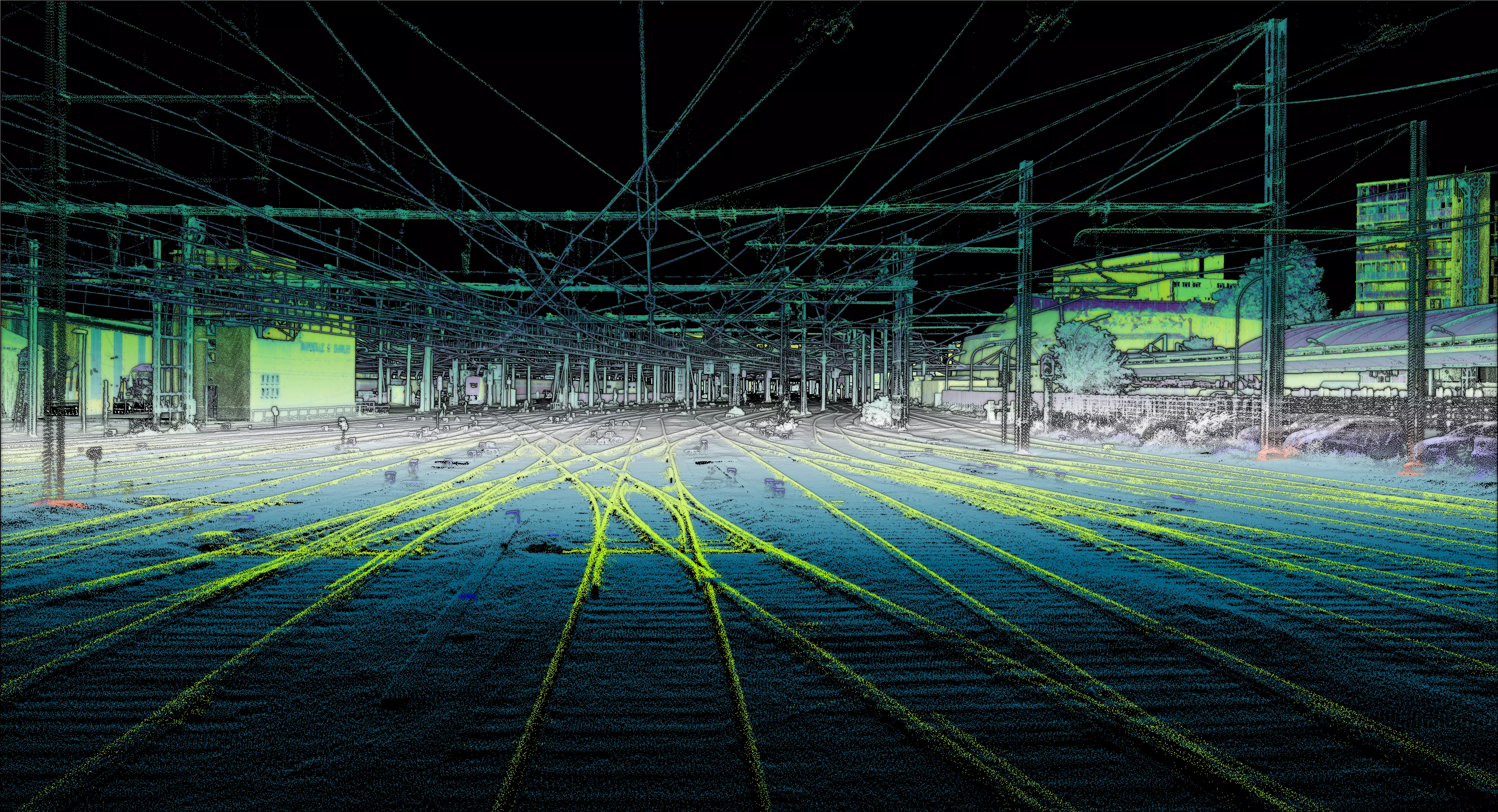

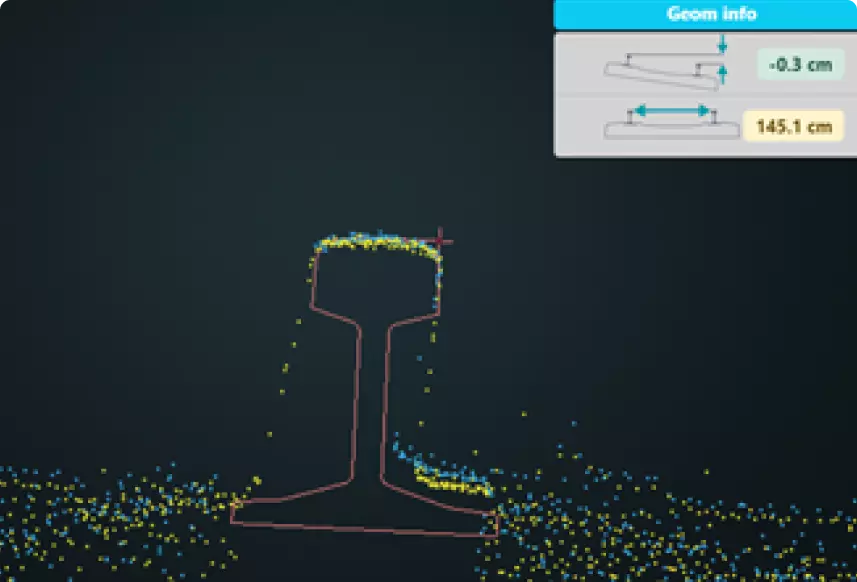

This type of rapid and seamless visualization over a large area allows for the quick identification and correction of defects. In the deliverables, light tones correspond to high temperatures and cool tones to low temperatures. The client was able to very easily and quickly identify the defective heaters.

**Left Image: Preview of Deliverables Provided to the Client for Lyon Part-Dieu and Lyon Perrache Stations.**

Thermal inspection provides an overall view of the installations, increases productivity, and optimizes the availability of agents, who can then focus solely on verifying sensitive areas. It also allows for chronological monitoring of defects. For instance, a post-maintenance inspection can ensure the effectiveness of the maintenance work.

Since the inspection tours are conducted over a very short period from early October to late November, it is crucial to plan drone inspection missions well in advance. To facilitate the use of our services, we have established a framework agreement with SNCF Réseau.

Have you not yet scheduled the inspection tour for your switch heaters ?

Don't delay any longer!